APMON Technology

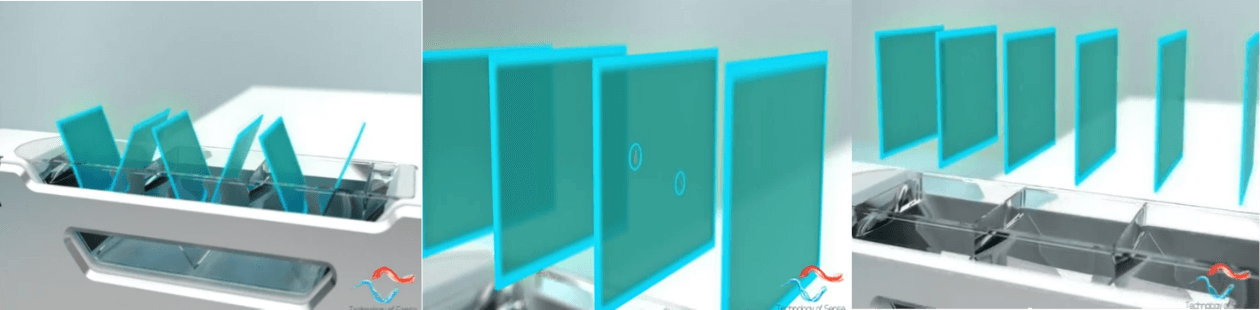

The APMON sensor collects the deposited particles on inclined glass witness plates in the cartridge. Particles stick to the position where they landed due to Van der Waals forces. By taking regular pictures of these witness plates the additional particles can be measured. Holographic imaging makes it possible to do this for all witness plates in one three-dimensional picture.

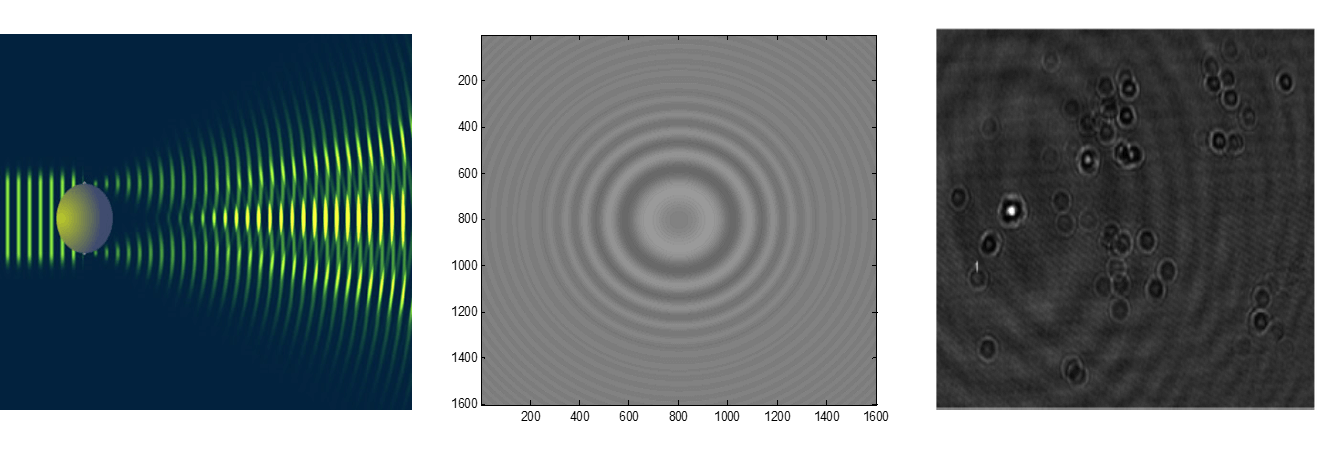

Holographic Measurement Method: Coherent laser beams that pass the surface of a particle are mixed with undisturbed laser beams and detected.

The image below shows a diffraction pattern from which using Fourier transformation methods the change of the real image can be reconstructed. The result is the particle size distribution of the particles that are deposited since the previous measurement (5 minutes before).

Products

Brookhuis provides products, services and support to improve and control the operational quality of cleanrooms and clean controlled environments. The products for real-time particle deposition monitoring are based on APMON Technology. APMON systems consist of a base computer and one or more sensors.

The APMON systems monitor the deposition of particles that are not removed by the ventilation system of the cleanroom or clean controlled environment.

The present APMON systems for monitoring the particle deposition rate in a cleanroom in operation are: